Last Updated on 2021-03-09 by Harry Masterton

You don't have to look far in your woodworking workshop before you find yourself thinking of electric hand planer uses to cut down your workload.

The electric power planer was first introduced in the late 1930's by Skil as the Skil 100 and was used predominately for shaping surfboards.

Today's modern power planer is primarily used for fast removal of stock, shaping up rough lumber for finer work and getting the heavier jobs done around your DIY projects.

Fencing, decking, framing, flooring and fitting doors are all electric hand planer uses where the power planer excels and saves time, blood sweat and tears!

You'll also find plenty of electric hand planer uses around the job site and remodeling projects. No self respecting jobsite framing joiner or remodeling contractor will be without his or her electric planer whether that's a corded handheld electric planer or more likely these days a cordless planer.

Electric Hand Planer Uses

Where the electric hand planer excels is removing stock, shaping rough lumber and doing it quickly.

What a power planer is not good it is fine woodworking. The power tool is a huge time saver in any woodworking workshop but when it comes to furniture and cabinet making the finesse of the manual wood planer and bench planer still reigns supreme.

Planing with an electric hand plane is a different experience to that of planing with a smoothing plane. The cut depth on a manual plane is much finer whereas the planing depth on a Wen Planer as an example may only be incremental in 1/64″

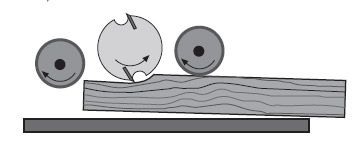

How Does A Power Hand Planer Work

A power hand planer is similar in form and function to a manual hand plane. It's one of the few woodworking power tools that does have a similar shape to its manual cousin.

In its most basic form the electric hand planer has a fixed rear shoe that sits on the lower cut level as the handheld planer makes its pass and a front shoe that has depth adjustment for cutting depth. The front handle acts as a depth adjustment knob to raise and lower the cutting blade or planer blade.

The front she will often have V shaped groves to facilitate the easy chamfering of stock edges.

A motor drives the cutter head with two reversible knives or carbide blade that are controlled by the on/off switch or trigger.

These reversible carbide blades will have a cutting width of normally 3 1/4″ like the Bosch PL1632 or the DIY orientated Ryobi HPL52K although some larger machines like the Makita 1806B have a 6 3/4″ cutting width

The cutter head spins at 10,000 to 20,000 Revs per Minute depending on the make and model of power planer.

Attachment accessories will normally include a parallel fence bracket or edge guide to run along the edge of the workpiece.

In the more sophisticated higher end electric hand planers designed for jobsite and professional use the planer will often by fitted with a brushless motor and be cordless powered by single or twin batteries. Both DeWalt and Makita make an excellent range of cordless planer.

Electric Hand Planer Uses

Learning how to use a power hand planer is slightly different to using a manual woodworking hand plane. First of all there are different safety factors to consider.

With a powerful electric motor that can spin at up to 20,000 revs per minute or RPM. Sure you can cut yourself on a planer knife but twin knives spinning at 20,000 RPM can do some serious damage to your fingers.

Make sure your lumber is clamped well to avoid any movement while you're working

Now that we've got that out of the way let's take a look at some serious electric hand planer uses.

The basic job of a power planer of course is to remove wood from your lumber, resizing and smoothing it. The electric hand planer is the power version of the humble block plane, scrub plane and jack plane.

The power plane will remove and smooth your boards and stock in a fast and efficient way saving time and energy along the way.

You can use a corded planer to trim your boards to size, smooth rough lumber that has just been sawn and with practice can be used as a jointer.

For the serial DIY'er the power planer has a wide variety of uses around the home, particularly if you're taking on a home remodeling project.

An electric hand planer is incredibly useful when it comes to fitting doors. With an edge guide fitted you'll find a power planer an absolute boon when it come to fitting large doors and fine tuning a pair of double doors to close correctly.

If you're fitting cabinet doors or remodeling a kitchen then the electric planer with a fine depth of cut will save hours of frustration.

Electric Hand Planer Tricks

Learn to use winding sticks with an electric hand planer.

It's not a substitute for the elevated skill of leveling a board with a hand plane and winding sticks but its quicker, there's les sweat involved and will allow you to use the side you have flattened as a reference to then push your board thru a thickness planer or benchtop planer if you have one.

Learn how to control a power planer.

The belt sander is notorious for grabbing the stock and throwing it across your shop and in a similar way an electric hand planer will grab your stock and either throw it or dig in. To avoid the plane tilting and to keep it flat especially when you're starting on a rough piece of board start with finer cuts at first.

Make sure you've got a firm but relaxed hold on the front handle to keep the front shoe flat, let the motor and blades spin up fully while you're pushing evenly forward with the rear handle until you feel the blades bite.

As you feel the blade start to bit put a little more pressure on the front handle to keep both front and rear shoes parallel and avoid ‘gouging' at the start of the cut.

If you don't do this the rear shoe will drop as the spinning knives bite.

If you're a gun owner or practice with firearms the analogy I often use is getting the planer started straight and keeping it controlled and level is a little like learning how to ‘squeeze' the trigger on a firearm rather than ‘snatching' the trigger and losing aim.

As the rear shoe engages with the stock apply equal pressure to both front and rear handle to keep the cut even.

As you get to the end of the pass and the front show passes over the end of the stock put more pressure on the rear handle to keep the cut level and avoid the front of the plane dipping and digging in causing ‘snipe'.

Once the spinning knives have passed over the end of the board lift off and release the trigger. That way you'll avoid snipe.

You should have a nice level even cut along the length of your lumber!

How To Use A Power Hand Planer On Wide Boards

If you want to know how to how to flatten a board with a power planer and how to plane wide boards with an electric hand planer then finding the high spots and eliminating twists is essential.

Use either a flat rigid straight edge to mark the high spots or again grab those winding sticks.

Use a marker or pencil to highlight and mark the high spots and start with fine passes checking constantly.

Flattening Slab With Power Planer

When we talk about ‘slab' in the woodworking shop we are normally referring to un-edged lumber that has been raw cut from the tree and then seasoned or maybe kiln dried although a slab from an exotic species is probably best left to season or dry naturally.

A natural wood slab like this is referred to as a ‘live edge' slab.

What Is A Lumber Slab Used For.

A live edge slab is usually used to make a top for a large decorative furniture piece such as a desk, dining table or even a bench. You might choose a home grown slab like American Walnut, Black Walnut, Black Cherry or even Pecan.

Exotic species include English Oak, Eucalyptus, Jarrah (a beautiful red hard wood found predominately in South Western Australia) and many more.

Image Source: Indo Gemstone on Flickr. Well worth a visit!

Flattening a large slab that's going to be used for a table or desk top with a power planer takes patience and a good eye.

As usual when you're taking on a large piece of lumber that you want to flatten start with a straight edge to mark out the real high spots, twists and warps that have set into the slab during seasoning. And then move on to a good set of winding sticks.

If you're looking for a really fine finish then there's absolutely no doubt that you'll need a combination of an electric hand planer and a Number 8 Bench Plane.

Take a look at this video by James Wright as he sets out to flatten an 11ft long by 50″ wide table top made up from 2 Oak Slabs.

Using Electric Hand Planer As Jointer

If your limited to setting up a small woodworking shop and you don't have room for a bench top jointer then jointing with electric hand planer is a great option.

If you are considering jointing with electric hand planer there are a couple of things to take into consideration.

Setting Up Your Hand Planer As A Jointer

To use your electric hand planer effectively as a jointer on long boards it has to be set up correctly.

The Hand Planer As A Jointer Step By Step – For Long Boards

- Set up your planer edge guide

- Fix a board bench edge to the bench front

- Use shims to raise the board

- Clamp using an Irwin quick grip

- Take minimal cuts

Watch Eric Sorensen set up his electric hand planer to plane long boards ready for jointing.

How To Make An Electric Hand Planer Into A Bench Top Jointer.

This is a cheap but effective jointer jig for your electric hand planer that you can make in your own woodworking shop.

It's quite simple to make from scrap wood off cuts, a couple of pieces of angle iron or aluminum. You'll also need a few screws and bolts that you'll probably have in your parts drawers and a short Velcro strap.

In this video by Eric Sorenson he actually uses an old puppy collar!

To make this easy to use yet accurate jointer jig for your power planer you'll need some simple tools.

An electric drill, small band saw, scroll saw or coping saw, a drill press, table saw and miter saw will also help but if you don't have any of these woodworking power tools as yet then you will manage with woodworking hand tools.

What Causes Snipe On A Planer?

Images Source And Article: Understanding Snipe at Highland Woodworking

It can happen with a thickness planer in particular but with an electric hand held planer snipe is caused by applying too much pressure on the rear handle of the plane as the cutter starts to bite.

And then at the end of the pass by too much pressure on the front handle which causes the front shoe to dip and dig the knives in to the end of the board.

Can You Use An Electric Hand Planer To Remove Paint?

Electric Hand Planer Uses – Removing paint and old finish. Because of the heat caused by the planer knives spinning and melting the paint, varnish or old finish on the board there is a danger of clogging the blades and damaging them.

It may be better to use your belt sander to get under the surface of the paint first or use a good quality paint stripper to remove the bulk of the finish.

If you are going to use you power planer to remove old finish then make the initial pass deep enough to cut into the wood that is under the finish.

As you're doing this make sure to continually check the blades to make sure they're not clogged and clear any debris.

If this is a large surface then you'll probably be better starting with an older set off blades first until you've lifted the majority of the paint and you can start to see bare wood.

Hand Planer Vs Electric – The Final Cut

In any good woodworking shop there is a place for woodworking power tools and woodworking hand tools.

There is absolutely no doubt that the electric hand planer has revolutionized woodworking particularly for the hobby woodworker and weekend DIY warrior. The power plane comes into its own particularly in the small woodworking shop.

Need more? Check our article How To Use An Electric Hand Planer here

The electric plane has also found great acceptance with building contractors on the jobsite.

There is no clear cut answer however to the hand planer vs electric because both tools have a place in your woodworking shop. Both the manual hand planer and the electric hand planer have skill sets that are worth learning and mastering.

The electric planer will remove a lot of stock and shape a board quickly but there's nothing like the finish or finesse that you can achieve when you're well practiced with a well set up hand plane.

Leave a Reply